INTERNATIONAL® S13®

INTEGRATED POWERTRAINTHE INTERNATIONAL® LT® WITH THE S13® INTEGRATED POWERTRAIN LEADS THE ON-HIGHWAY AERO CATEGORY IN FUEL ECONOMY BY AT LEAST 5%.*

The International® S13® Integrated Powertrain is our most advanced, fuel-efficient and streamlined powertrain, available in the LT®, RH™, HX®, and HV™ series.

In fact, the International® LT® with the S13 Integrated Powertrain leads the on-highway aero category by at least 5% in fuel economy.*

Capable of up to 515 hp and 1,850 lb-ft of torque, the S13 Integrated consists of an engine, transmission and aftertreatment system designed together to maximize integration between systems while allowing each component to perform its function. The result is a new standard of efficiency, profitability and sustainability for our on-highway and off-highway customers.

Designed and developed from the ground up by a global dream team of engineers and proven over more than 4 million miles across a variety of terrains, the S13 Integrated is the last diesel powertrain we will ever produce—and, without question, our best.

OPERATING ECONOMY

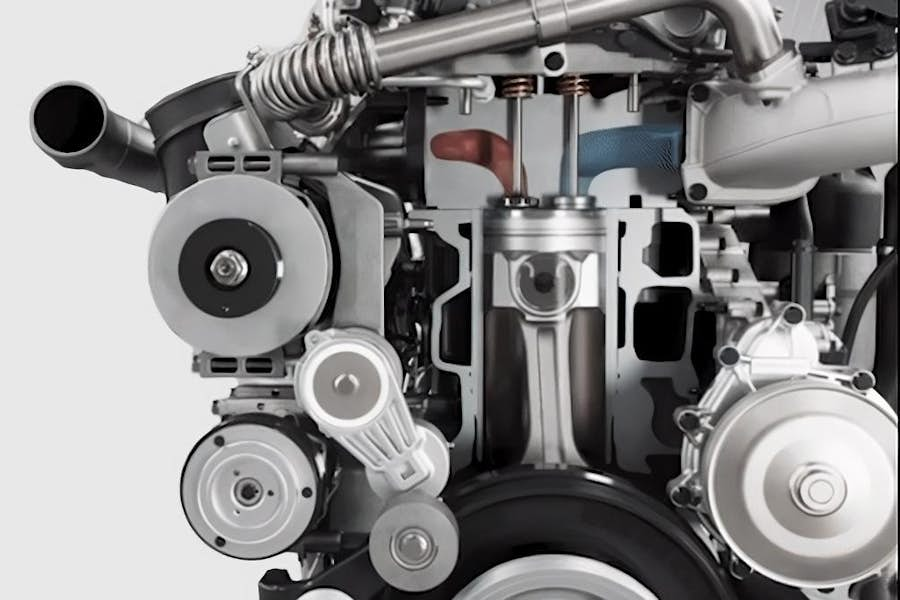

Through extensive testing, a new cylinder and piston head design with maximum cooling properties was created. This new double overhead cam design directly equates to less fuel being consumed. But that’s not all. Thanks to the new Dual Stage Aftertreatment system, the heavy and expensive EGR cooler is no longer needed to reduce emissions. Its absence means a more reliable and robust engine that maximizes exhaust flow through the turbo to enhance performance and efficiency.

Delivering the goods

The S13 Engine can operate at low rpm with high torque which equates to less fuel consumed while still delivering up to 515 hp and 1,850 lb-ft of torque. This incredible engine brings undisputed economy through its unique, clean burn technology.

HARD AT WORK

The S13 Integrated Powertrain is taking business to the next level across a wide range of industries. Learn how it’s powering the LT, RH, HX and HV Series today.

Explore trucks

Keeping the driver comfortable, informed and empowered has been a mantra at International for decades as part of our DriverFirst™ Philosophy. The S13 Integrated Powertrain takes it a step further by offering a smooth and quiet operation with superior capabilities. In fact, full torque is available at only 900 rpm and the transmission’s wide overall gear ratio means optimal efficiency on a variety of terrain while still delivering low speed performance. And when descending, drivers can rely on the new compression release brake to deliver strong, secure braking power up to 470 hp.

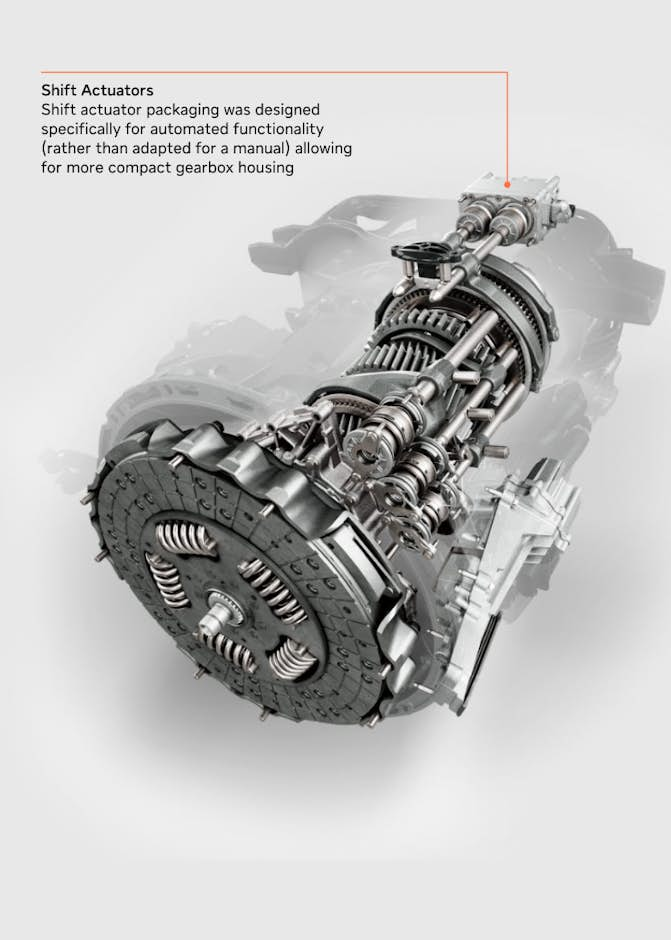

Making the shift

The fully automated T14 transmission was designed in-house from the ground up. It’s a 14-speed overdrive transmission that is optimized to deliver peak fuel economy performance in direct drive (13th gear) during typical load, while still allowing the ability to go into overdrive when lightly loaded or empty. The transmission has an electronically controlled clutch actuator that works in sync with the engine to deliver faster, smoother shift performance. Since it does not consume air during complicated maneuvers — like when you’re backing a trailer into a tight loading dock – the driver never needs to stop and let the air recharge. The T14 also uses an integrated oil to water coolant system to optimize temperature regulation in both hot and cold environments.

AFTERTREATMENT SYSTEM

The entire powertrain was designed to allow each individual component — engine, transmission and aftertreatment — to focus on doing what it does best. Eliminating the EGR cooler is a prime example. Instead of trying to control NOx emissions inside the cylinder, the engine operates with zero EGR during regular operation, so it can focus on generating more power. Plus, no EGR during normal operations means 100% of the exhaust flow goes through the turbo allowing the use of a simple, more reliable fixed vane turbocharger.

Next-gen aftertreatment

Because there’s no EGR during regular operation, NOx must be treated a different way. To do this, the engineers developed an all-new Dual Stage Aftertreatment design that injects a first dose of DEF just downstream of the turbo in the evaporator tube and a second dose inside the aftertreatment container. Since cooled EGR has been eliminated from the combustion chamber, much less soot or particulate matter is generated. This allows for extended service intervals and eliminates the need for active regens. In fact, the cleaner combustion cycle generates so much less soot the engineers were able to eliminate the need for a diesel oxidation catalyst (DOC) in the aftertreatment system. Combined, the aftertreatment system provides a simple, reliable solution that’s easily serviceable.

EVERY DETAIL ENGINEERED TO PERFECTION.

EFFICIENT COMBUSTION CYCLE

The S13® Integrated engineers paid special attention to the design of the combustion chamber and exhaust posts to enhance the performance and efficiency of the engine. Through extensive testing, a new piston head with maximum cooling properties was created that when combined with a new double overhead cam design, directly equates to less fuel consumed.

STREAMLINED TRANSMISSION

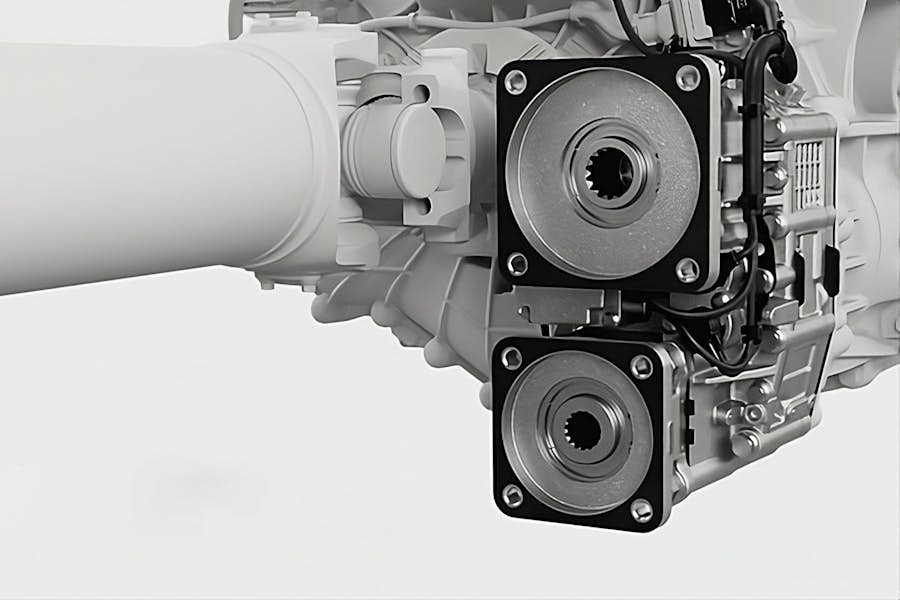

The S13® Integrated’s T14 Transmission features a revolutionary design. The reverse gearing is accomplished by using the planetary gears which helps reduce the overall weight and size of the unit, making room for chassis packaging and PTO.

INCREASED PAYLOAD AND POWER

Thanks to comprehensive engineering and choice of materials, the S13 Integrated Powertrain is remarkably light in weight. This helps trucks equipped with the S13 Integrated to achieve an outstanding payload capacity, along with improved fuel economy — attributes that can make a real difference to your bottom line. Plus, any International truck equipped with the S13 Integrated can be ordered with several different PTO options (including a dual option) installed directly at the factory and carrying the same warranty as the transmission.

S13® INTEGRATED IN MOTION

S13® INTEGRATED WALKAROUND

DUAL STAGE AFTERTREATMENT SYSTEM

SHIFT WHAT'S POSSIBLE

MEETING OF THE MINDS

IT ALL COMES TOGETHER

S13® INTEGRATED AND HX SERIES

Several versions of the S13 Integrated Powertrain can be ordered — each with a different horsepower rating, allowing you to match the right engine to your specific application. All versions provide abundant torque at low RPM that is maintained through peak horsepower, giving drivers the muscle they need for the toughest jobs.

View vehicle-specific torque curves in the specifications below.

SPECIFICATIONS

S13® Engine Technical Specifications

-

Engine TypeDiesel, 4-Cycle

-

ConfigurationInline 6-Cylinder

-

Displacement12.7L (777 cu. in.)

-

Bore and Stroke5.12 in. and 6.30 in. (130 mm & 160 mm)

-

Compression Ratio23:1

-

AspirationFixed Geometry Turbocharger

-

Combustion System1800 bar Common Rail

-

Engine Lubrication47.5 quarts (45L)

-

Total Engine Weight(Dry) 2,284 lb. (1,036 kg)

-

Valves4 Valves Per Cylinder, Dual Overhead Camshaft

-

B10 Design Life1,200,000 miles (1,931,000 km)

Industry Leading Engine Warranty

-

Base Engine24 months, unlimited miles, unlimited hours*

-

Base Major Components60 months, 500,000 miles (800,000 km)***

-

Base Towing24 months, unlimited miles, unlimited hours**

-

Optional EngineUp to 72 months, 600,000 miles (960,000 km)***

-

Optional Major ComponentUp to 84 months, 700,000 miles (1,120,000 km)***

T14 Transmission Benefits

-

Deep low-end gearing and shifting smoothness, delivering efficiencies of a direct drive in an overdrive package

14-speed with 2 crawler gears

Lightweight, efficiently packaged and robustly designed

Single countershaft design for simplicity and reliability

Vocational specific drive modes including paver, off-road and split shaft

LT and RH Series

-

Gear

Ratio

% Step

R2

12.60

R1

16.23

1

20.81

29%

2

16.16

29%

3

12.57

29%

4

9.76

29%

5

7.56

29%

6

5.87

29%

7

4.55

29%

8

3.53

28%

9

2.77

29%

10

2.15

29%

11

1.66

29%

12

1.29

29%

13

1.00

28%

14

0.78

-

LT and RH Series Power and Torque Curve

-

HP @ 1800 RPM

TORQUE [LB-FT] @ 900 RPM

GOVERNED SPEED [RPM]

370

1250

2000

400

1450

2000

400

1850

2000

430

1550

2000

450

1750

2000

470

1750

2000

515

1850

2000

HX Series

-

Gear

Ratio

% Step

1

20.81

29 %

2

16.16

29%

3

12.57

29%

4

9.76

29%

5

7.56

29%

6

5.87

29%

7

4.55

29%

8

3.53

28%

9

2.77

29%

10

2.15

29%

11

1.66

29%

12

1.29

29%

13

1.00

28%

14

0.78

-

R Gear

Ratio

R6

4.59

R5

5.91

R4

7.61

R3

9.81

R2

12.60

R1

16.23

HX Series Power and Torque Curve

-

HP @ 1800 RPM

Torque [LB-FT] @ 900 RPM

Governed Speed [RPM]

400

1450

2000

430

1550

2000

450

1750

2000

470

1750

2000

515

1850

2000

LT and RH Series T14 Transmission Base Warranty

-

Transmission60 months, 750,000 miles (1,200,000 km)***

-

Clutch36 months, 350,000 miles (563,000 km)***

HX Series T14 Transmission Base Warranty

-

Transmission, Clutch and Transmission Mounted PTO Base Warranty (includes towing)****Less than 52K rear axles rating: 36 months, unlimited miles, unlimited hours

-

Greater than or equal to 52,000lb. rear axles rating: 24 months,, unlimited miles, unlimited hours

Dual Stage Aftertreatment Key Benefits

-

The Dual Stage Aftertreatment system allows the powertrain to focus on what it does best: delivering power- when and where you need it.

- DPF service intervals extended due to less soot produced by the engine

- No diesel oxidation catalyst, no fuel dosing

- Easy access to DPF for easy serviceability

DPF filter does not need to be cleaned/replaced until 650,000 miles @ >8.2 mpg

Robust, compact aftertreatment allows less heat loss and helps significantly in improving the fuel economy and packaging

Dual Stage Aftertreatment Warranty

-

24 months, unlimited miles, unlimited hours

*Fire and rescue applications: 60 months or 100,000 miles (160,000 km), whichever comes first

**Towing for vehicles with engine failures

***whichever comes first

**** Warranty only applicable to factory installed PTOs

RUN WITH US

Curious about the next big launch? Recent innovations? Subscribe to our newsletter and get the latest news on our products and services direct to your inbox.

Subscribe