eMV™ SERIES

ELECTRIC POWERED.

Built on the tried, tested and trusted MV™ Series, the International® eMV™ Series is the perfect electric truck for medium-duty applications. Clean energy fuels up to 342 peak hp and 1,737 lb-ft of torque, delivering zero emissions from operation to application. An optional ePower system provides the perfect foundation for continuous-energy needs like refrigeration while the ePTO converts power for a wide range of applications, including boom and other hydraulic applications. The eMV Series bridges toughness and technology to reduce costs like fuel and maintenance and improves uptime.

- Typical range: 135 miles*

- Peak power: 342 hp, 1,737 lb-ft torque

- 210KWh Lithium Iron Phosphate (LFP) Battery**

- 3 levels of regenerative braking

- Acceleration equal to or better than diesel

- Battery Thermal Management System (BTMS) using standard red coolant

- Lower maintenance compared to diesel

- Available turn-key charging solutions from International® team of experts

*Actual range is based on environmental conditions, driving behaviors, diminishing loads and maximum use of regenerative braking, etc.

**210 kWh powertrain battery option with a reserve held for base charge protection. Actual range is based on environmental conditions, driving behaviors, etc.

BODY POWER OPTIONS

MAKE EVERY JOB ELECTRIC.

STANDARD SAFETY FEATURES

STEEL SANCTUARY

The eMV Series cab wraps your crew in a high-strength, low-alloy (HSLA) reinforced, cold-rolled steel construction that combines the corrosion resistance of aluminum with the world-class fit, finish, and strength of steel. The result is a larger, quieter, more protective interior with air- and water-tight seals.

InterCoat® ChemGuard

Think of it as a self-healing layer of skin on our galvanized steel. This inter-reactive, chrome-zinc phosphate coating is used on floor and toe kick panels to help extend integrity. The self-rejuvenating properties allow surface cuts, scratches, and perforations to maintain corrosion protection.

Optional spray-on floor protection

This available polyurethane and polyurea formulation creates a protective tray on the cab floor that contains spills, as well as any of nature’s elements that make their way inside. Durable and long-lasting, the optional spray-on liner is an OEM-grade protective coating designed to guard against abrasion, corrosion, and impact and can be found on millions of pickup bedliners.

TOP-DOWN STRENGTH

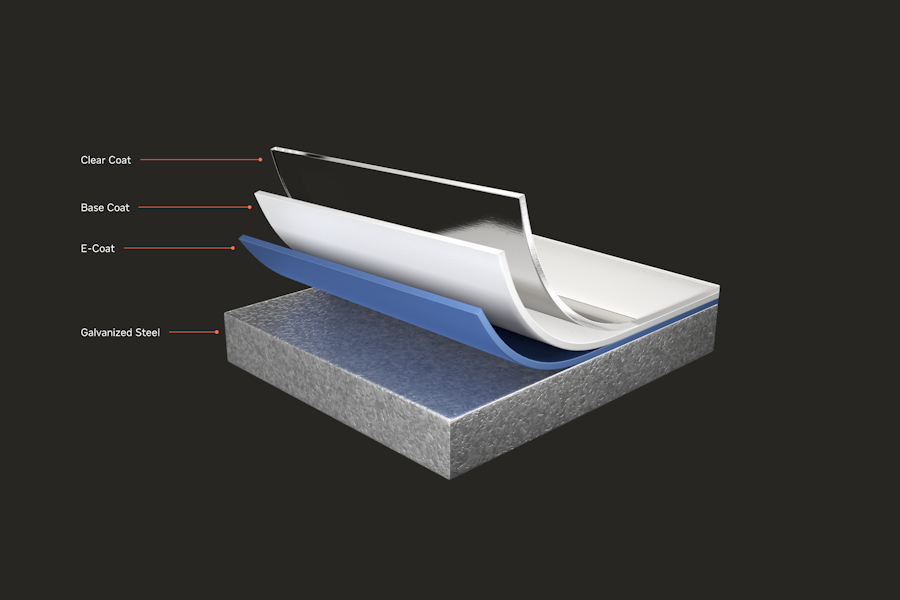

DURABILITY RUNS DEEP

At International, longevity is the head of the hammer. Which is why every welded eMV Series cab assembly is dipped into an electrostatically-applied primer as part of a rigorous paint, sealing, and coating process that provides superior corrosion and fade resistance – all backed by a 5-year perforation corrosion warranty.

Corrosion protection process

- Stamped steel with 60G/60G dual sided galvanized coating - standard on dash and toe and floor panels

- Custom-engineered caustic and surfactant formula cleans and preps the steel

- Proprietary tri-metal (nickel, zinc, manganese) phosphate blend provides robust corrosion protection and the first level of pain adhesion

- Epoxy-based electrodeposition primer, or e-coat, is applied. This covers and seals the entire exposed metal surface of the cab

- Acrylic basecoat

- Urethane clear coat

BRAKING FEATURES

It's no secret electric vehicles require less maintenance. With substantially fewer parts, an electric vehicle simply does not have the maintenance or service requirements of an internal combustion engine product. Plus, thanks to regenerative braking, the standard brakes can last much longer between service intervals.

Take these services off your plate:

- No engine oil maintenance

- No transmission maintenance

- No fuel and air filters

- No turbos, no EGR, no injectors

- No engine air filters, no MAF and no O2 sensor

- No aftertreatment

LED HEADLAMPS

LED headlamps offer a variety of advantages including a longer life span. For businesses that work in inclement weather conditions and heating elements make sure the lenses stay clear of snow and ice to help ensure a strong beam of light.

SLOPED HOOD

A sloped hood design helps provide enhanced forward visibility during both day and night, increasing jobsite safety.

CORROSION PROTECTION

A ChemGuard coating applied to the galvanized steel provides self-healing properties when it comes to some scratches, cuts, and perforations. An optional spray-on liner coating is applied to the inside floor and creates a protective tray that can contain spills and melted snow.

Exterior

STEERING WHEEL

The steering wheel adds more functions at the driver’s fingertips with integrated back-lit, laser etched labeling for improved durability and visibility. Plus, all the controls within the cab are designed to be operated easily while wearing gloves.

FLAT INSTRUMENT PANEL

A standard flat instrument panel includes a center-mounted vent to keep the middle passenger comfortable while providing space for extra legroom or a large floor-mounted body control module.

PUSH BUTTON GEAR SELECTOR

Offers precise, split-second shifting capability with the push of a button.

SWITCH PANEL

Switch panel comes standard with 3-level regenerative braking, off-road traction control, suspension dump & lift gate.

- Large, easy-to-read backlit text

- Warning lights can be any of seven colors

- Any switch can be relocated by the customer without wiring changes using Diamond Logic

- Blank “windows” available for custom labeling

INTERIOR

SECONDARY AIR SYSTEM GAUGE

POWER VS REGEN SELECTION

Indicates how much power is being used by the motor when accelerating or how much power is being returned to the batteries during regenerative braking.

PROPULSION LOAD %

RANGE ESTIMATE

BATTERY TEMP INDICATOR

DRIVE MOTOR TEMPERATURE INDICATOR

REGENERATIVE BRAKING INDICATOR, LEVELS 1, 2, 3

12-VOLT BATTERY GAUGE

DISPLAY

BUILD YOUR OWN eMV SERIES TRUCK

Customize and equip your truck with the components, options and specifications you need to get the job done.

START BUILDING

SPECIFICATIONS

Strength

-

GVWR

25,999 - 33,000 lb.

Configurations

-

Axle Configurations4x2

-

Cab/Sleeper ConfigurationsDay Cab

-

Models

MV60E, 107.9"

BBC, 40" BA -

Cab Interior Trim

Classic

Diamond -

Wheel BaseDry Van

272" / 112" typical (26' box)

254" / 106" typical (24' box)

236" / 100" typical (22' box)

217" / 100" typical (20' box)Service Body217"

Drivetrain

-

Battery SystemHigh voltage - 210kWh Lithium Iron Phosphate with dedicated HVAC system

609-volt operating system -

Drive SystemDana Motor

-

FrameHeat-Treated Alloy Steel 120,000 PSI

-

Front AxleDana Spicer I-Beam: 12,000 lb.

-

Front SuspensionSpring, Parabolic Taper Leaf: 12,000 lb.

-

MotorDirect Drive Electric Motor

Peak Motor Torque - 1,737 ft-lb

Continuous Motor Torque - 730 ft-lb -

Rear AxleSingle Rear AxleDana Spicer: 23,000 lb.

RAR (Rear Axle Ratio): 6.83 -

Rear SuspensionIROS Air Suspension

21,000 lb. single axle with shocks

Other Components

-

Auxiliary Battery Systems12 volt, 2 AGM Batteries- Recharged through high voltage system

-

BrakesAir Brakes with ABS

4 channel Electronic Stability Program with Traction Control -

HeadlampsLED Headlamps

-

Steering GearSheppard M100

-

TiresContinental

Available Warranties

-

Standard Warranty

Drive Battery, Drive Motor and Drive Charger and Cables: 36 months/150K kWh*

*GDT=350,000 hours

Gross Discharge Throughput, reflected in kilowatt-hours (kWh): Total energy discharged from the battery. -

Additional Optional Warranty AvailableSee dealer for details

YOUR ROADMAP

TO ELECTRIFICATION

We understand that transitioning a commercial fleet to electric is a complex process. That's why we have a team to guide you through the entire process — from consulting and charging to customer onboarding, training and beyond.

LEARN MORE

ADDITIONAL INFORMATION

EXPLORE MORE TRUCKS

MORE THAN 1,000

PLACES TO TURN

A network of more than 1,000 dealers across North America is standing by. Filter by sales, service, and parts to find a dealer to help you maximize your truck’s potential.

FIND A DEALER